SNEHT

Direct optical method for spectral emissivity measurement

as a function of temperature.

The basic parts of the experimental setup of the method are an FTIR spectrometer, a laboratory black body, a laser system for sample heating and a system for contact and non-contact measurement of sample surface temperature. The method enables to analyze both bulk materials and coatings deposited on bulk substrates in the temperature range of 250°C – 1000°C and spectral range of 1.38 – 26 um.

Unique method developed by our team

SNEHT method is the result of our research.

Result of international significance

Evaluation according to methodology M17 + of The Council for Research, Development and Innovation of the Czech Republic

Demanded for research collaborations worldwide

The method is demanded by the world’s leading companies, universities and research centers.

Detailed Specification

MEASUREMENT SYSTEM

Description of the measurement system

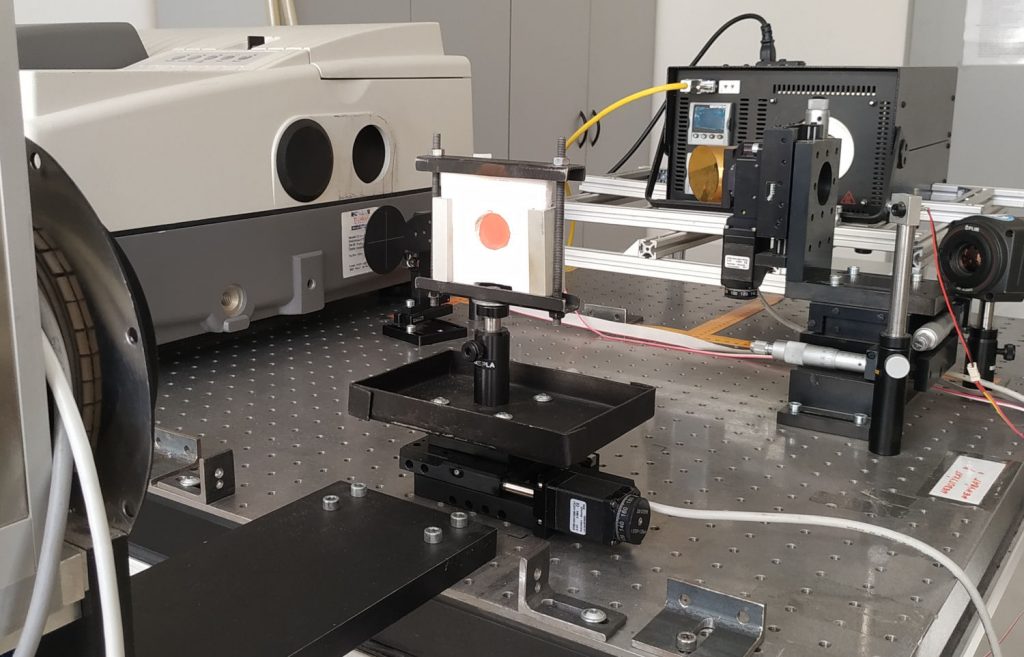

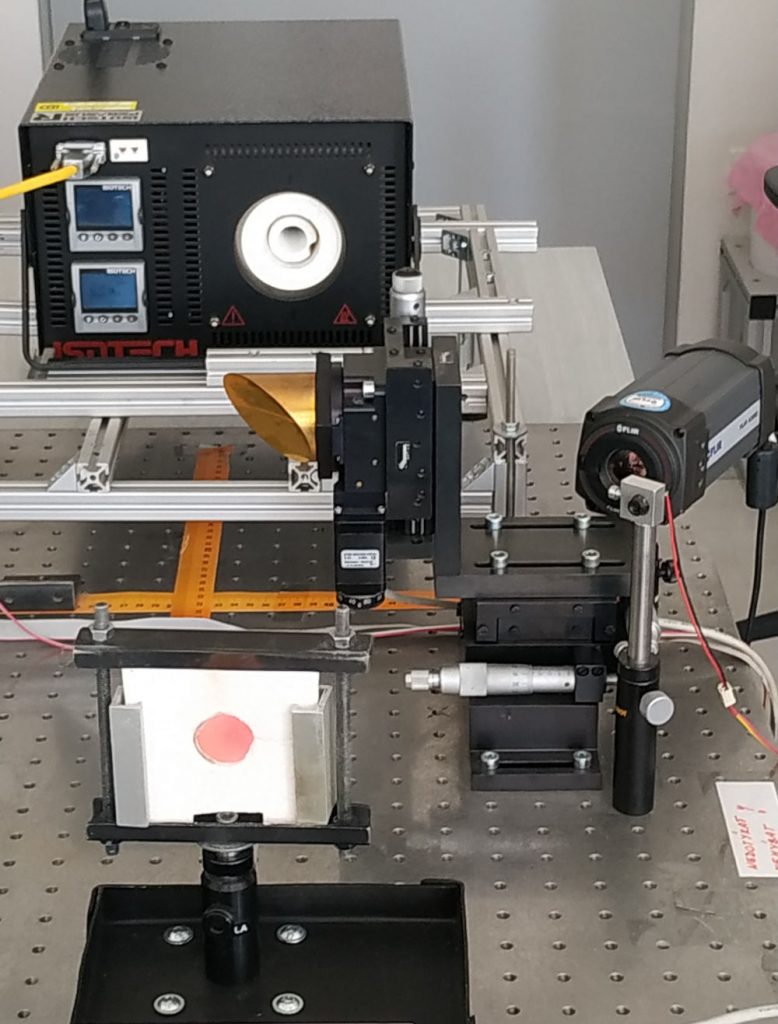

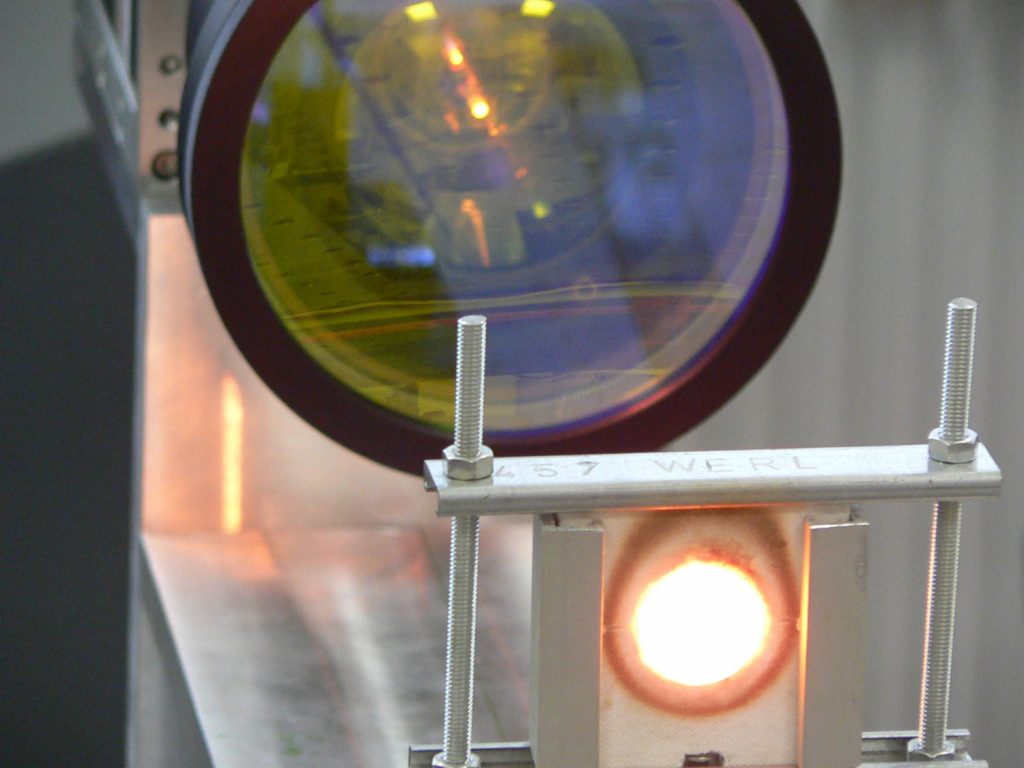

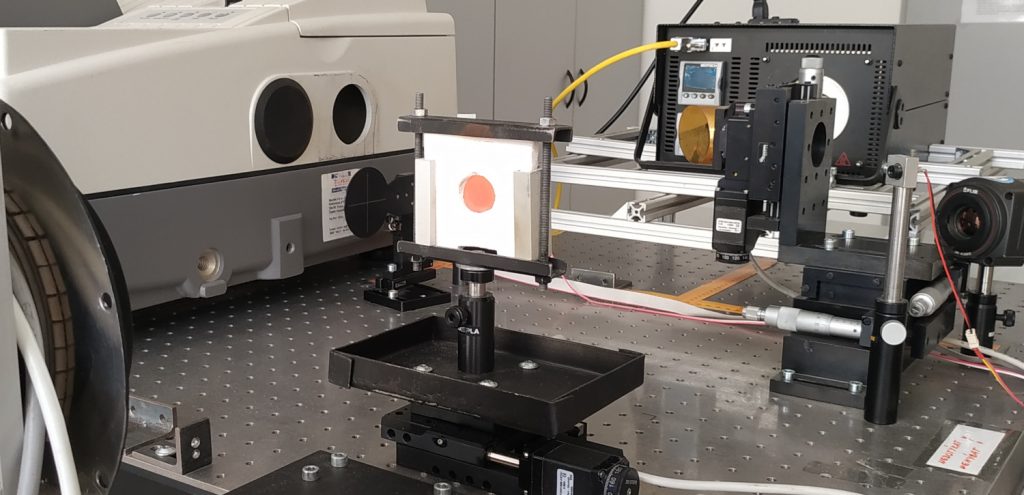

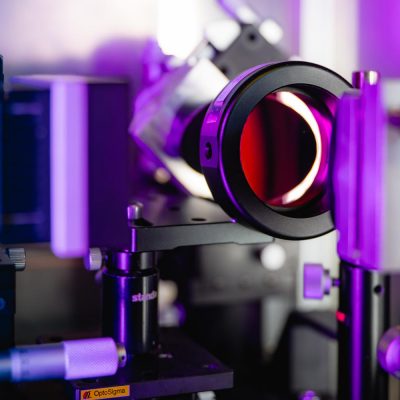

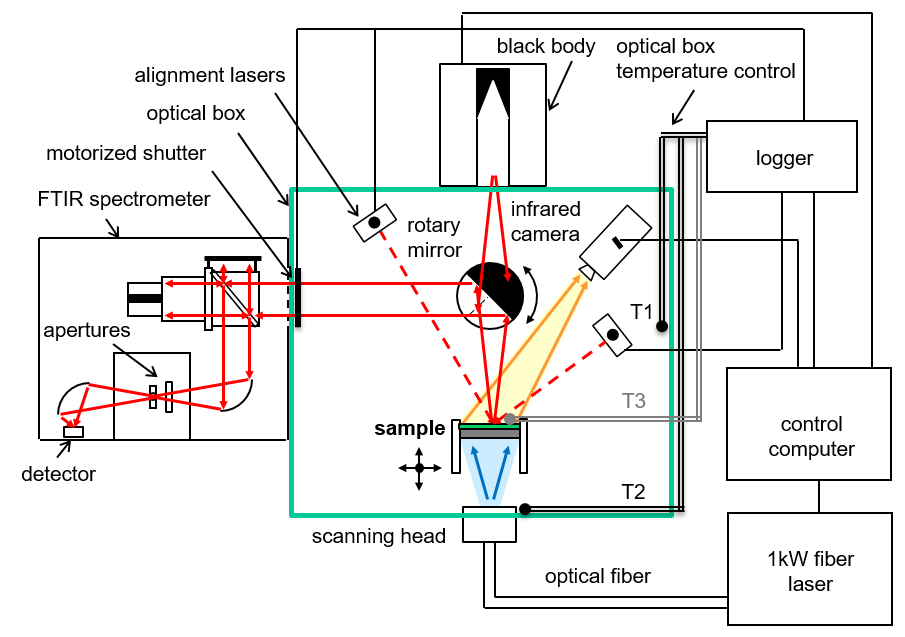

The reference radiation source and the sample are placed against each other outside of the spectrometer. In the middle between them, there is inserted a rotary parabolic mirror, which collects radiation alternately from the two sources while preserving the same optical path. The collected radiation from the source is incident through an external port (can be closed by motorized shutter) and spectrometer sample space (apertures) on the detector. The optical path is covered by an optical box. The optical box temperature is controlled at two places (near the laser scan head for the sample heating and at a point between the sample and the infrared camera) by unsheathed calibrated thermocouples.

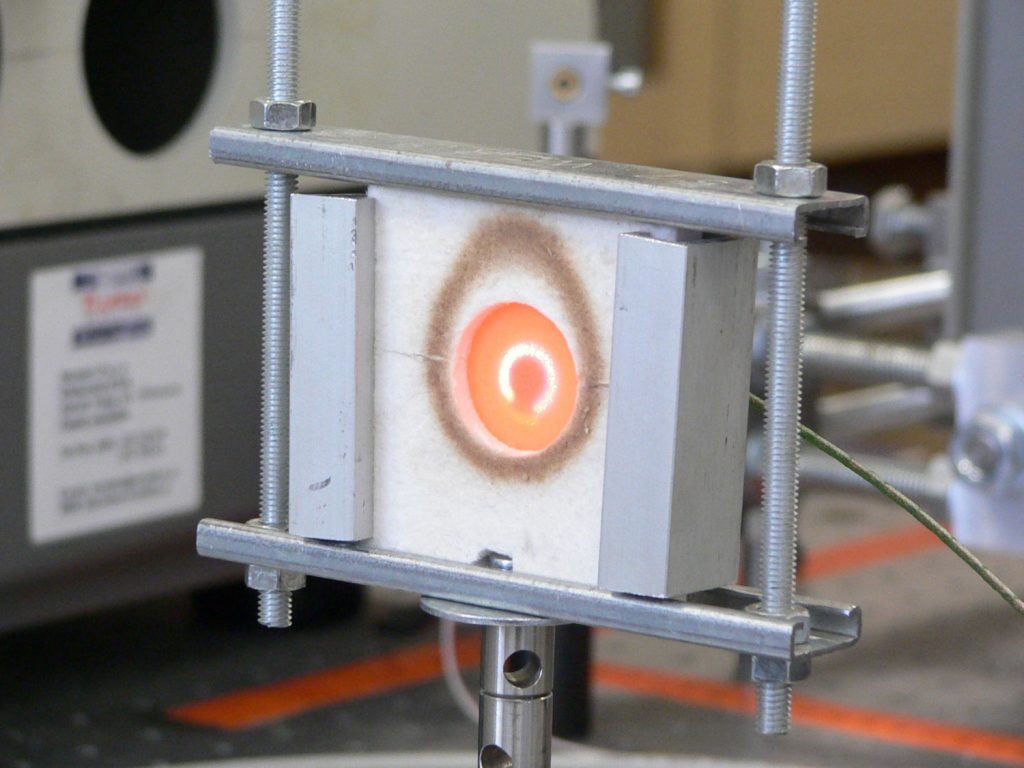

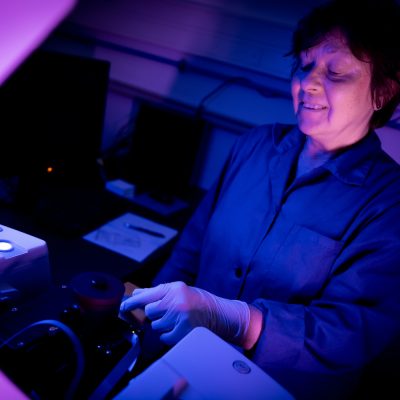

The measured sample is placed in a holder made of ceramic fibre insulation, which is mounted on an optical table so that it is possible to precisely position it by linear translation stages and a mounting rod. Heating of the sample is realized by the fibre laser with the scanning head. The desired sample temperature is achieved by controlling the laser power. The desired homogeneous temperature field on the front side of the sample is achieved by an appropriate choice of time-space laser beam movement across the back side of the sample.

Surface temperature of the sample is measured by several methods. The first method uses an infrared camera and a reference coating with a known effective emissivity coated on one half of each sample. Another method is based on a contact temperature measurement by a thermocouple welded to the surface of each sample. The last method combines Christiansen effect with contact and non-contact temperature measurement systems.

Components of the measurement system

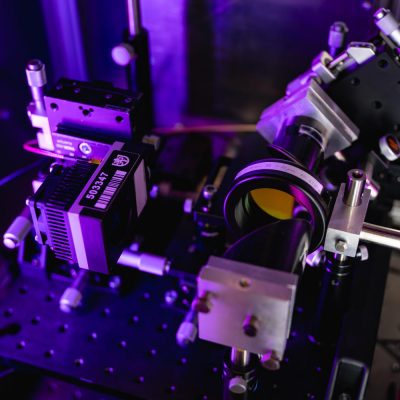

| detection system | Nicolet 3700 FTIR spectrometer |

| reference radiation source | Laboratory black body Pegasus R970 |

| laser system of sample heating | 1kW fibre laser, scanning head |

| system for sample surface temperature measurement | FLIR A320 infrared camera (thermocouple measurement system Adam 4018) |

| opto-mechanical components | Sample holder, rotary parabolic mirror, motorized and manual micro-positioners, motorized shutter, alignment lasers, thermocouples, optical apertures and optical box |

SpecifiCATION

Temperature range

250°C – 1000°C, depending on the measured sample (shape, size, thermal conductivity).

Wavelength range

| T 300°C | 2.5 – 26 μm |

| T 400°C | 2.0 – 26 μm |

| T 500°C | 1.8 – 26 μm |

| T 600°C | 1.66 – 26 μm |

| T > 700°C | 1.38 – 26 μm |

Measured quantity

- Spectral normal emissivity

Computed quantities

- Band normal emissivity

- Total normal emissivity

- Spectral normal absorptivity

- Band normal absorptivity

- Integrated normal absorptivity

SAMPLES

Analyzed materials

- Opaque coatings (thickness of tens to hundreds of micrometers) on a bulk substrate

- Semitransparent coatings (thickness of tens to hundreds of micrometers) on an opaque bulk substrate (measured is emissivity of coating – substrate system)

- Ceramics

- Metals

- Insulators

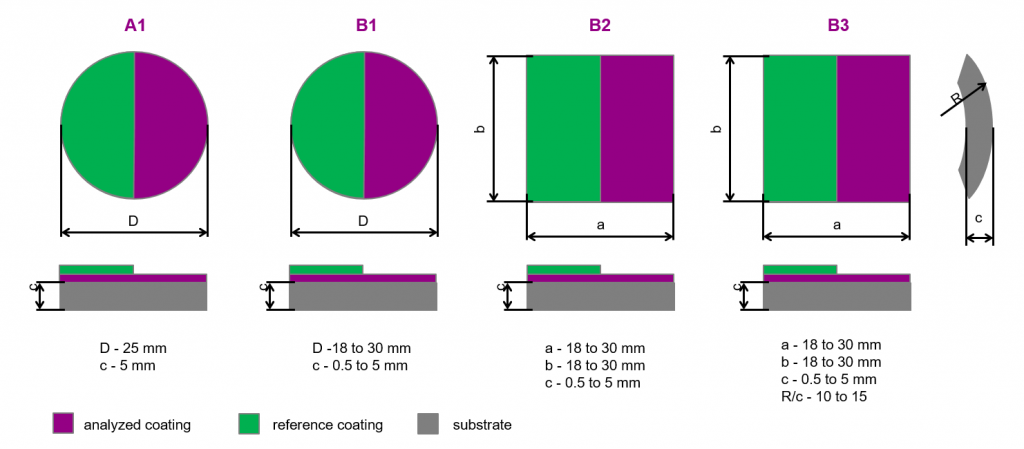

Dimensions and shapes of samples

Standard samples

| A1 | Circular samples with a diameter of 25 mm and a thickness of 5 mm – Standard substrates – refractory steel CSN 41 7153, blasted on the front side |

NonStandard samples

| B1 | Circular samples with a diameter of 18 – 30 mm and a thickness of 0.5 – 5 mm |

| B2 | Square samples with an edge size of 18 – 30 mm and a thickness of 0.5 – 5 mm |

| B3 | Square samples with a small curvature and edges with size of 18 – 30 mm and a thickness of 0.5 – 5 mm |

| B4 | Individual dimensions and shapes of samples |

Additional requirements for samples

- Analyzed bulk materials and substrates must not transmit radiation with a wavelength of 1064 nm and must withstand the required thermal load

- Maximum roughness of the part of the sample, on which will be applied the reference coating is Ra = 5 um, Rz = 35 um

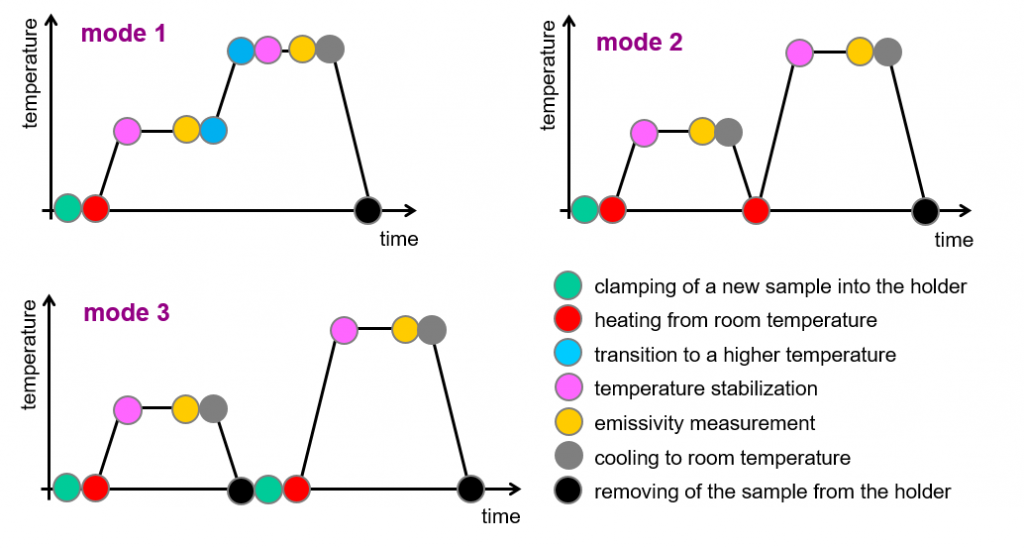

TEMPERATURE MODES

Temperature modes

| mode 1 | Step heating of one sample – increasing of the temperature from 300°C to 1000°C with a temperature step of 100°C |

| mode 2 | Heating of one sample with temperature cycling – cooling to room temperature before raising the temperature to the next temperature level |

| mode 3 | Heating of new sample at each temperature level – a new sample is heated from room temperature directly to the next temperature level |

| mode 4 | Individual time and temperature mode – on demand defined sequence of time and temperature steps of sample heating and emissivity measurement |

RESULTS

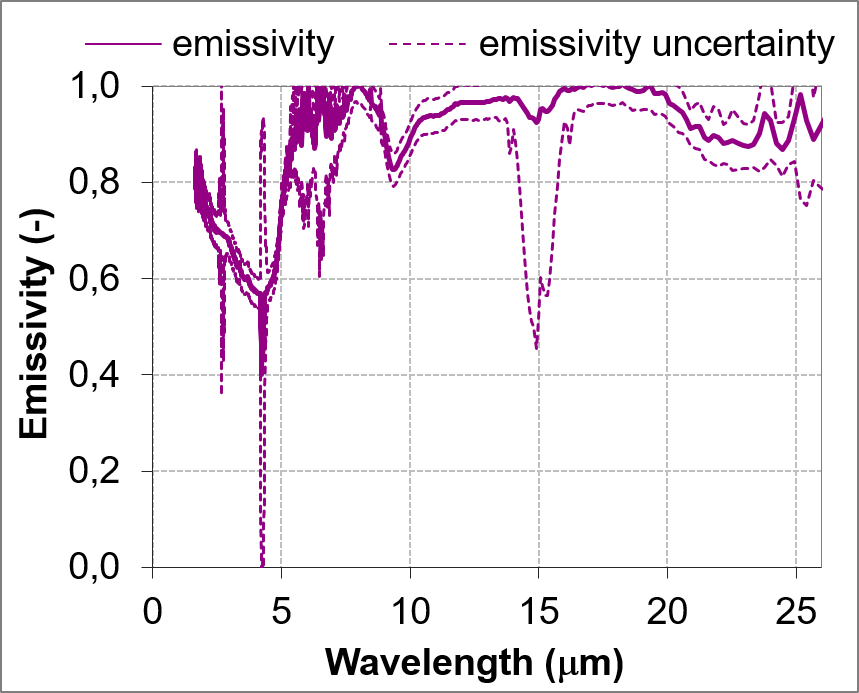

Method output

- Spectral normal emissivity – graphical display of spectral emissivity distribution (separately for each measurement) and data in electronic form;

- The spectrum is influenced by atmospheric absorption (higher uncertainty) in the bands of 2.5 – 2.95 um, 4.17 – 4.5 um, 4.8 –7.9 um and 13.2 – 17.2 um

Form of the results

Basic

- Measurement protocol in electronic form in PDF format or in printed form – example

- sXLSX file that contains a measurement protocol in electronic form and emissivity values including measurement uncertainty

Extended

- Technical report in electronic form in PDF format or in printed form; the report contains description of method and measurement procedure, measured samples, summary of results of all measurements, discussion of the results and conclusions of the research